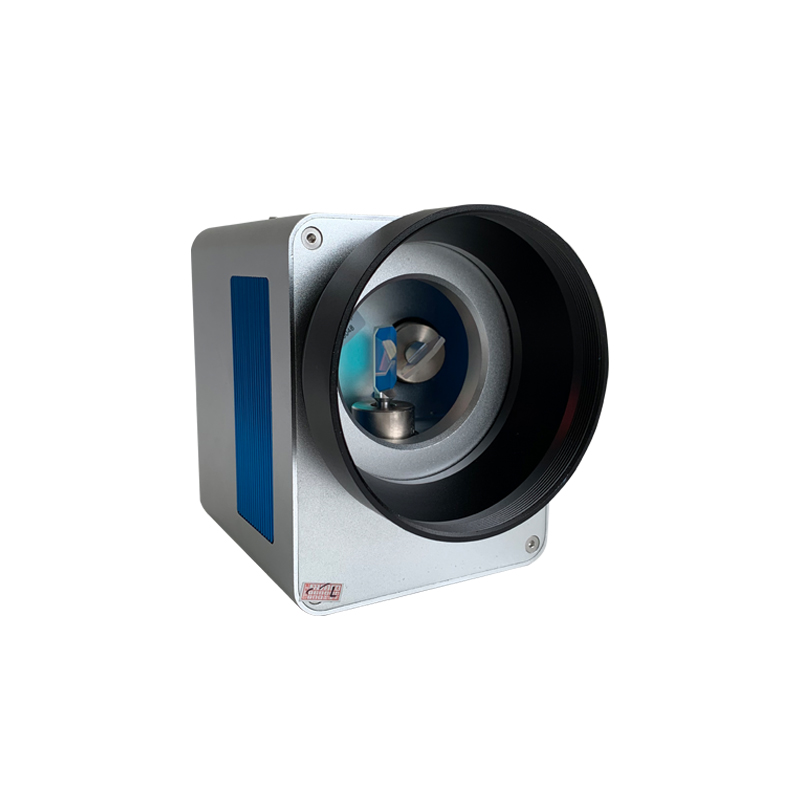

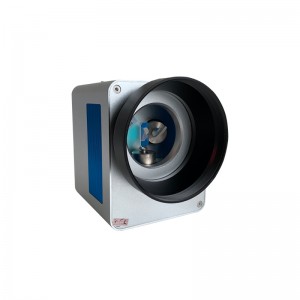

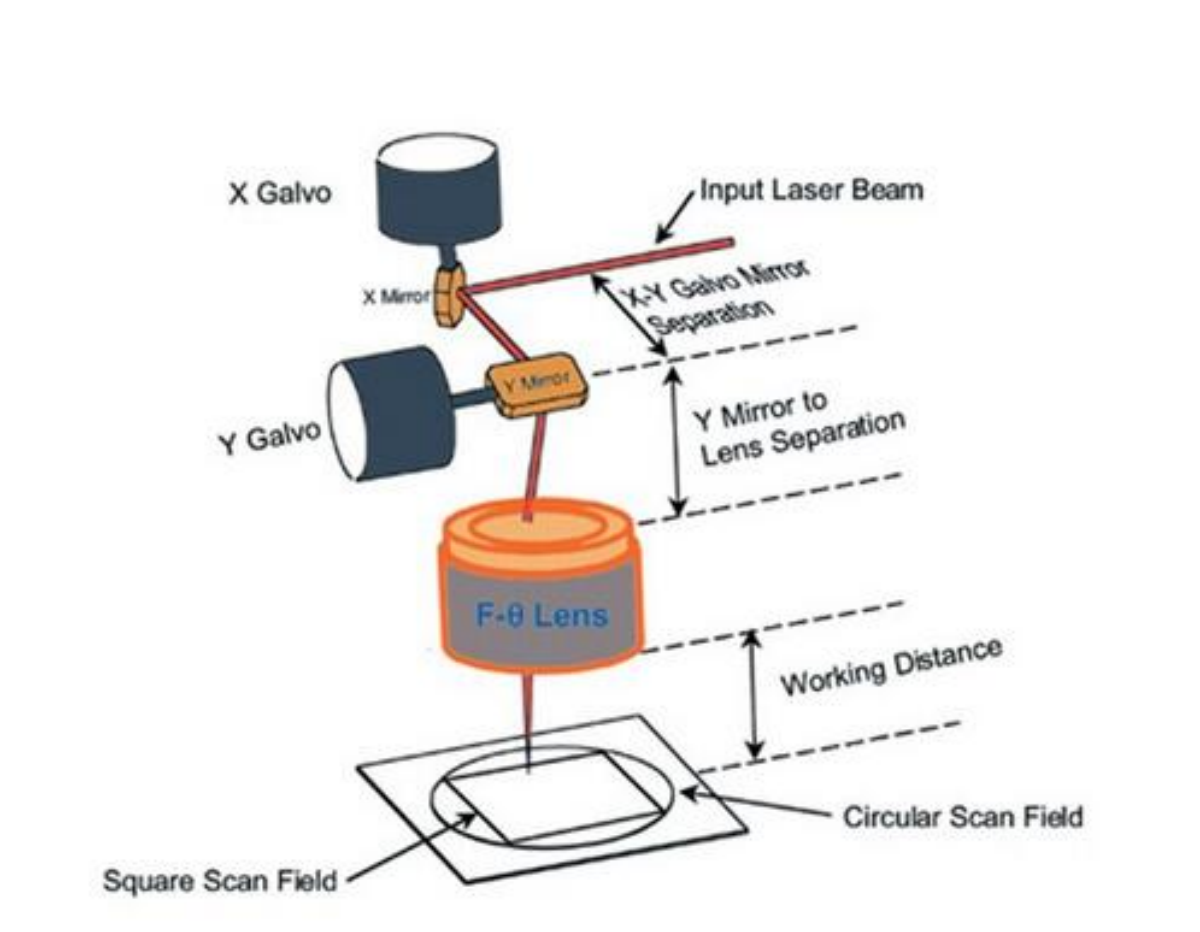

High speed 10mm laser marking engraving galvo scanner head

Features

1. Low noises, high linearity and low drift

2. Modular design, easy installment and maintenance

3. Support varieties of F-theta lenses

4. Available to XY2-100

5. High-cost performance

The 10mm galvo scanner has good running stability, high positioning accuracy, fast marking speed, strong anti-interference ability, the overall performance of the scanner has reached the international leading level in this field. The advantages are as following:

1.Adopted the photoelectric sensors

2.Good linearity, lower drift, high resolution and repeat positioning.

3.Accurate load design for 10 mm mirrors, high accuracy of the motor assembly, reasonable structure, very small static friction coefficient, and zero offsets, all ensured the best dynamic characteristics for the whole system.

4.Drives with advanced detection ability of position and speed greatly improved the dynamic response performance and scanning speed of the whole system.

5.Design of overload, over-current, and reverse connect protection, makes the system running more reliable.

6.The whole system adopted the optimization Designing of electromagnetic compatibility, with a high signal-to-noise ratio and strong anti-interference ability.

7.This scanner system solved the common problems of motor temperature drift, signal interference, and zero drift, etc.

Application

The laser marking engraving galvo scan head can be widely used in laser marking, laser engraving, laser drilling, laser cutting, micromachining, medical aesthetic, ophthalmic imaging, 3D printing, etc.

Parameters

|

Aperture (mm) |

10 |

|

Max. scan angle |

±12.5° |

|

Small step response time (ms) |

0.22 |

|

Rotational inertia (g*cm2·±10%) |

0.25 |

|

Max. RMS Current (A/axis) |

25 |

|

Peak current (A) |

15 |

|

Zero drift (μRad./C) |

<15 |

|

Scale drift (ppm/C) |

<50 |

|

Linearity |

≥99.90% |

|

Repeatability (μRad.) |

<8 |

|

Long-term drift over 8 hours (mRad) |

<0.5 |

|

Operating temperature |

25℃±10℃ |

|

Weight |

1.2kgs |

|

Input power requirement (DC) |

±15V @ 5A Max RMS |