200W 300W MOPA Water Cooling Laser Cleaning Machine

Features

1. Simple software, select prestored parameters directly

2. Prestored all kinds of parameter graphics, six kinds of graphics can be selected: straight line/spiral/ circle/rectangle/rectangle filling/Circle filling

3. Easy to use and operate

4. 12 different modes can be switched and selected quickly to facilitate production and debug

5. The language can be optional, English / Chinese or other languages (if required)

6. The laser cleaning machine is more compact in designing with smaller size and lighter weight.

7. The laser cleaning machine body is made of high-quality sheet metal and the key support parts are reinforced for more durability.

Application

1. In the field of industrial production, mechanical equipment has been in service for a long time, and a large amount of oil, waste paint, rust and carbon deposits have accumulated on the surface of parts and components. Laser cleaning technology greatly improves the carbon deposition effect and welding process quality. It can efficiently clean the carbon deposition on the surface of different substrates, reduce welding defects, and improve the weldability of materials; at the same time, it can also save the production cost of the enterprise, to enhance the production efficiency of the enterprise.

2. In the field of microelectronics processing, polyimide is the dielectric material for the internal connection structure of electronic component packaging films.

3. The precision machinery industry often needs to remove esters and mineral oils used for lubrication and anti-corrosion on parts, usually by chemical methods, and chemical cleaning often still has residues. Laser degreasing can completely remove esters and mineral oil without damaging the surface of parts.

Parameters

|

Parameter name |

Parameter value |

|

Laser type |

Domestic nanosecond pulse fiber |

|

Maximum output power(W) |

200/300 |

|

Central wavelength (nm) |

1064±5 |

|

Power regulation range (%) |

10-100 |

|

Output power instability (%) |

≦5 |

|

Output power instability (kHz) |

10-50/20-50 |

|

Pulse length (ns) |

90-130/130-140 |

|

Maximum pulse energy (mJ) |

10/12.5 |

|

Conductive fiber length (m) |

5or10 |

|

Laser protection class |

4 |

|

Cooling mode |

water-cooling |

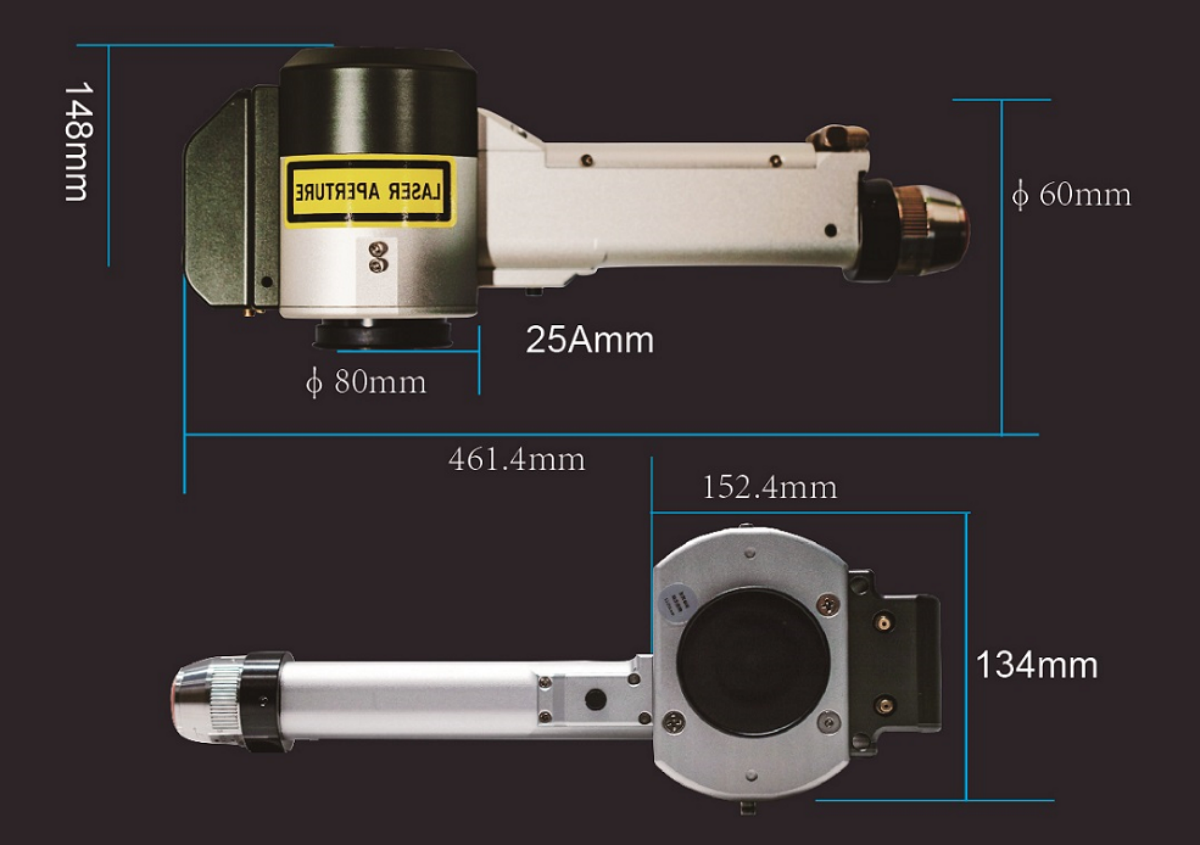

Structures

Laser cleaning head size: